We have been manufacturing vertical lathes and machining centres

For 74 years

TOSHULIN, a.s. is a leading manufacturer of technologically advanced, multifunctional CNC vertical turning lathes for machining mid- to large-sized workpieces. Working in collaboration with our customers, we design and manufacture machines to their specific requirements, to meet their machining challenges.

years of experience in the production of machine tools

machines sold globally

countries in the world where we have installed machines

dedicated, highly-qualified employees and partners all over the world

Production program

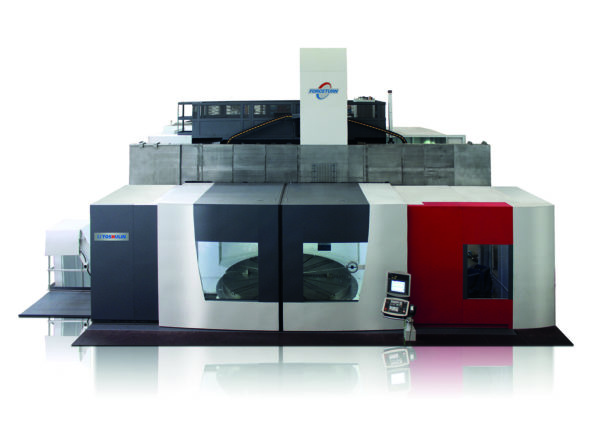

Our design team, together with our production and assembly teams, manufactures VTLs with table diameters from 800 mm to 4000 mm to the precise specifications of our customers. Our designs take into account the individual needs of each customer, increasing their productivity in even the most demanding circumstances.

Together with our sister company, TOS Kuřim, company we are able to manufacture gantry machining centres and vertical lathes with table diameters up to 16 000 mm.

TOSHULIN VTLs integrate all aspects of chip machining – turning, milling, grinding, and drilling – bringing a comprehensive machining solution to our customers.

Demanding Technological Applications With High Accuracy.

- Well-proven frame design which guarantees high rigidity and stability during machining

- High variability of tooling and measuring probes

- Automatic exchange of tool heads, tool holders and modular tools

- Tool magazine which can be configured to the customer’s requirements

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- As an option, the machine can be equipped with automatic pallet exchange

- Optional high-pressure cooling

- Completely closed machining area

- Possibility to connect an exhauster

- Extra travel range in the X-axis in both directions from the table centre

- Available control systems: Siemens or Fanuc

Effective Machining of an Extensive Workpiece Range.

- Frame with high rigidity and stability

- Design emphasizing functionality and easy maintenance

- Available C-axis control, and rotary tool drive

- Automatic exchange of turning tool holders and rotary tools

- Ram designed for efficient and precise machining

- Variable height of the working area

- Through-the-tool coolant supply optional

- Up-to-date and user-comfortable control

- Pre-defined configurations enable quick machine delivery

- Available control systems: Siemens or Fanuc

High-efficient machining of workpieces with large dimensions.

- High and stable machine frame from cast iron specified for high-efficient machining

- Optional guiding with bearing packs or hydrostatic guiding in the linear axes

- Ram is designed for the most efficient machining

- Extremely rigid table bearing using the hydrostatic bearing

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- Optional high-pressure cooling

- Great variability of tooling

- Automatic exchange of tool heads, tool holders and modular tools

- Extra travel range in the X-axis in both directions from the table centre

- Effective protective guards against splashing coolant

- Control systems Siemens or Fanuc

The Ultimate in Customization for Complete Machining Without Compromises.

- High degree to adapt the machine configuration

- Extraordinary rigid and stable machine frame from cast iron

- Ram designed for high-efficient machining

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- Optional guiding with bearing packs or hydrostatic guiding in the linear axes

- Table bearing – optional antifriction bearing or hydrostatic bearing

- Optional Y-axis control

- As an option, the machine can be equipped with automatic pallet exchange

- Extensive range of tooling and measuring probes

- Automatic exchange of tool heads, tool holders and modular tools

- Optional tool heads offer supplementary axes: B-head, C‑head, Y-head

- Machine accuracy adapted to the customer’s requirements

- Possibility to implement high-pressure cooling – HPC or UHPC

Extensive utilization possibilities